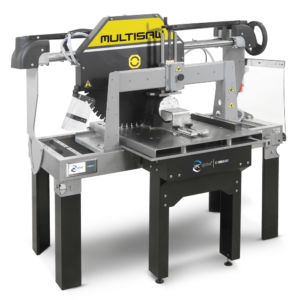

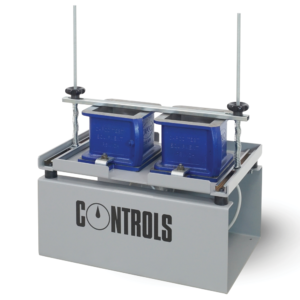

AUTOMAX PRO-M | EN Automatic Compression Tester for Cubes and Cylinders

$25,000.00

AUTOMAX PRO-M is CONTROLS’ top-of-the-range Compact-Line Compression Machine for automatic standard failure tests and advanced concrete mechanical properties assessment.

Smart automatic and connected, AUTOMAX PRO-M benefits from connective technologies that allow it to take inputs from ancillary measuring systems and devices so you can manage all your test data online, automatically, with no risk of transposing errors.

- DESCRIPTION

- Description

- Store Policies

- Inquiries

HIGHLIGHTS

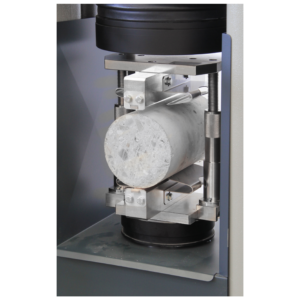

AUTOMAX PRO-M Power Control System is fitted with superior hydraulics. It can perform, in addition to standard failure tests, the Modulus of Elasticity Determination tests, Characterizations of Fiber Reinforced Concrete (FRC) under displacement-control and tensile tests on steel specimens.

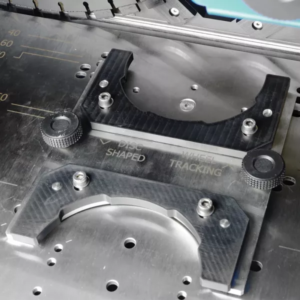

AUTOMAX PRO-M uses LinkLAB, CONTROLS’ proprietary Laboratory Connectivity Package which allows your testing system to be a connected part of your laboratory infrastructure by taking inputs from any number of ancillary measuring systems and devices increasing efficiency and eliminating transposing errors.

The machines consist of:

Frame

Four-column high stiffness welded frame tested for stability to EN 12390-4.

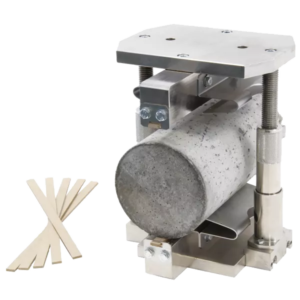

Heavy duty spherical seat in lubricating oil bath, allowing initial free alignment at the initial contact with the specimen and automatic jamming up to the end of test.

Compression platens

See table. A traceable certificate of surface hardness is available on request.

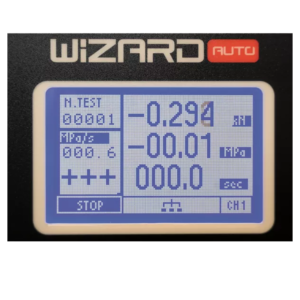

Automax PRO-M, Automatic power and control system

See technical specifications.

Safety features

Includes: Max. pressure valve to avoid machine overloading; piston travel limit switch; emergency stop button; front door and rear transparent fragment guard.

FEATURES

- Huge boost in efficiency and error elimination: LinK-LAB – Integrated testing station solution for seamless connection and data inputs from many ancillary devices for dimensional measurement, weight, bar code, etc.

- Fully automatic – time saving: Full test-cycle automation maximizes productivity and ensures tests are performed accurately according to pre-set methods, eliminating operator variables.

- Highly accurate and energy saving: Our DC motor technology quietly and efficiently delivers super accurate load control at both low-speed and low-loads.

- Intuitive, quick and simple operation: The integrated control system features an intuitive 7” color graphical display, which works like a tablet or smart-phone, and makes AUTOMAX PRO-M quick and simple to operate.

- Standards compliant – peace of mind: Automatic performance of Elastic Modulus tests according to the main International Standards with automatic calculation of tests results.

- Advanced: Allowing the execution of displacement-controlled tests on beams, notched beams, round or square slabs.

SPECIFICATIONS

Hydraulics

- DC motor, 720W, 50-60Hz

- Maximum working pressure 700 bar

- Load/unload electrovalve for test execution via display/PC and automatic stop at specimen failure

- Active control of up to 4 frames by selection via display/PC (third and fourth frame as option). See accessories.

- ES Energy Saving technology to reduce the power consumption and enable silent operation

- Flow-sharing technology to perform loading and unloading cycles at controlled rate

Hardware

- 524,000 points high-resolution/stability analog channels

- 6 channels to be factory configured:

- 2 channels for load sensors

- 2 channels for load or displacement/strain sensor

- 2 channels for displacement/strain sensors

- Control frequency 250 Hz

- Sampling frequency 250 Hz

- 7”, 800 x 480 pixel, 16 M colors, icon-driven capacitive sensing touchscreen graphic display

- Unlimited storage capacity for test data on internal 16 GB SD card

- USB port for test data storage on external USB memory stick and for firmware upgrade

- Ethernet port for PC / Internet /network communication

- Optional integrated graphic printer including Load-Time plot (for standard failure tests)

- RS 232 port for data downloading in ASCII format

PHYSICAL SPECIFICATION TABLE

| Model 50- | C47F02/M C47F04/M |

C57F02/M C57F04/M |

| Capacity kN | 2000 | 3000 |

| Max vertical daylight , mm* |

350 | 350 |

| Horizontal daylight mm |

350 | 370 |

| Max. piston travel*, mm | 50 | 50 |

| Platen dimensions | 310 x 510 x 50 mm. | 310 x 510 x 50 mm |

| Platen surface hardness | 55.5 HRC (600 HV) | 55.5 HRC (600 HV) |

| Platens flatness toll. | 0.05 mm | 0.05 mm |

| Overall dimensions, mm | 930x605x1530 | 1020x640x1550 |

| Weight approx., kg | 790 | 1160 |

*Use distance pieces conforming to the specimen size to avoid piston over travel

Platens

Calibration of Load Digital Readout Unit

Firmware upgrade for advanced test execution

PC Software

Printer

Distance Pieces

Electronic Universal Extensometer / Compressometer

Axial Compression Device

Extras and Upgrades

Third and Fourth Frame Facility

General Inquiries

There are no inquiries yet.