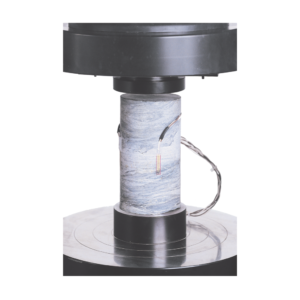

WIZARD AUTO | General Utility Standard Automatic Compression Testers for Cubes, Cylinders and blocks

$11,000.00

WIZARD AUTO is CONTROLS’ standard automatic Quality Control machine for compression and flexural testing. It includes many features and enhancements that makes this automatic system more ergonomic, user-friendly, efficient and energy-smart.

- DESCRIPTION

- Description

- Store Policies

- Inquiries

HIGHLIGHTS

QC testing performance has just taken a step change improvement with CONTROLS abandoning manual test control and now features automatic closed-loop PID control of loading-rate using VFD inverter-technology control of the high specification AC motor.

Wizard Auto automatically and accurately performs tests at the correct test speed, ensuring compliance to Standards and with no effect due to operator variables.

Main Benefits:

- Reduced opportunities for operator errors, improving accuracy of results and repeatability

- Easy-to-use: even for operators with limited expertise.

- Conforming to Standards: the machine automatically performs the test at correct test speed. Conformance to Standards can be easily proven.

- High performance: high speed pump closes the daylight above the specimen at the fasted speed allowing a very high throughput of tests.

- Operator comfort due to the significant noise reduction.

- Energy smart, with 50% reduction in energy consumption.

FEATURES

Main features include:

- Rigid welded steel construction

- Accuracy Class 1/A (EN/ASTM) starting from 10% of full scale (from 1% on request)

- Two channels for load sensors

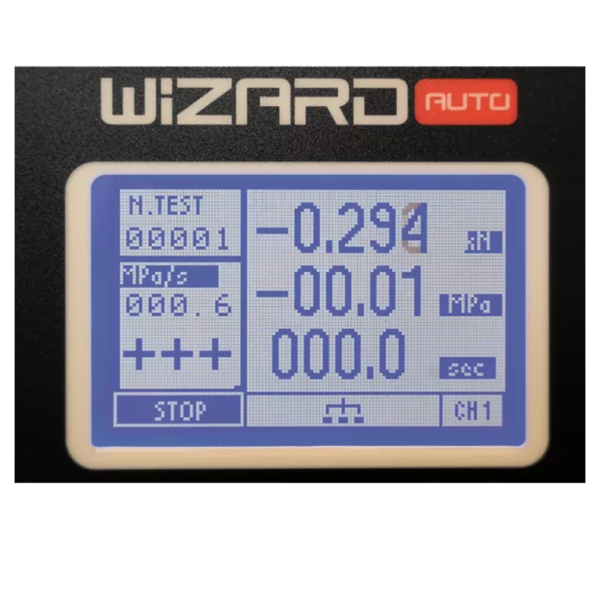

- Wide graphic display 128 x 80 pixel

- Graphic printer available as option

- AC motor fitted with VFD INVERTER device: high efficiency, low consumption, silent operation

- Dual stage pump for fast approach and automatic switch to high pressure for loading

- Second frame optional facility

Frame

Rigid welded steel construction. Spherical seat allows free alignment at the initial contact with the specimen.

Compression platens

See table. Traceable certificate of surface hardness available on request.

Safety features

Includes: Max. pressure valve to avoid machine overloading; piston travel limit switch; emergency stop button; front and rear flexible transparent fragment guard.

SPECIFICATIONS

Hydraulic

- Max pressure 700 bar

- Power 750 W

- Dual stage pump: low pressure/high delivery for fast piston approach and high pressure/low delivery for loading.

- AC motor fitted with VFD inverter device featuring high efficiency, reduction of power consumption and silent operation.

- Second frame optional facility using valve selector.

Hardware

- Two 16 bit analog channels for load sensors

- Wide graphic display 128 x 80 pixel

- Sampling rate 50 Hz

- Internal memory

- RS 232 port for data download (including load/time graph points) to PC in ASCII format

- Integrated printer as optional. See accessories

PYSICAL SPECIFICATION TABLE

| Model 50- | C35W02 C35W04 |

C45W02 C45W04 |

| Capacity kN | 3000 | 2000 |

| Max vertical daylight, mm | 350* | 350* |

| Horizontal daylight, mm | 355 | 335 |

| Max. piston travel*, mm | 50 | 50 |

| Platen dimensions, mm | dia. 220 | dia. 220 |

| Platen surface hardness | 55.5 HRC (600 HV) | 55.5 HRC |

| Platens flatness toll, mm | 0.03 | 0.03 |

| Overall dimensions, mm | W 795 x D 695 x H 1070 mm | W 865 x D 740 x H 1025 mm |

| Weight approx., kg | 834 | 746 |

*With accessory 50-C50/CYL vertical clearance is increased by 20 mm. See test accessories.

Platens

Calibration of Load Digital Readout Unit

Firmware upgrade for advanced test execution

PC Software

Printer

Distance Pieces

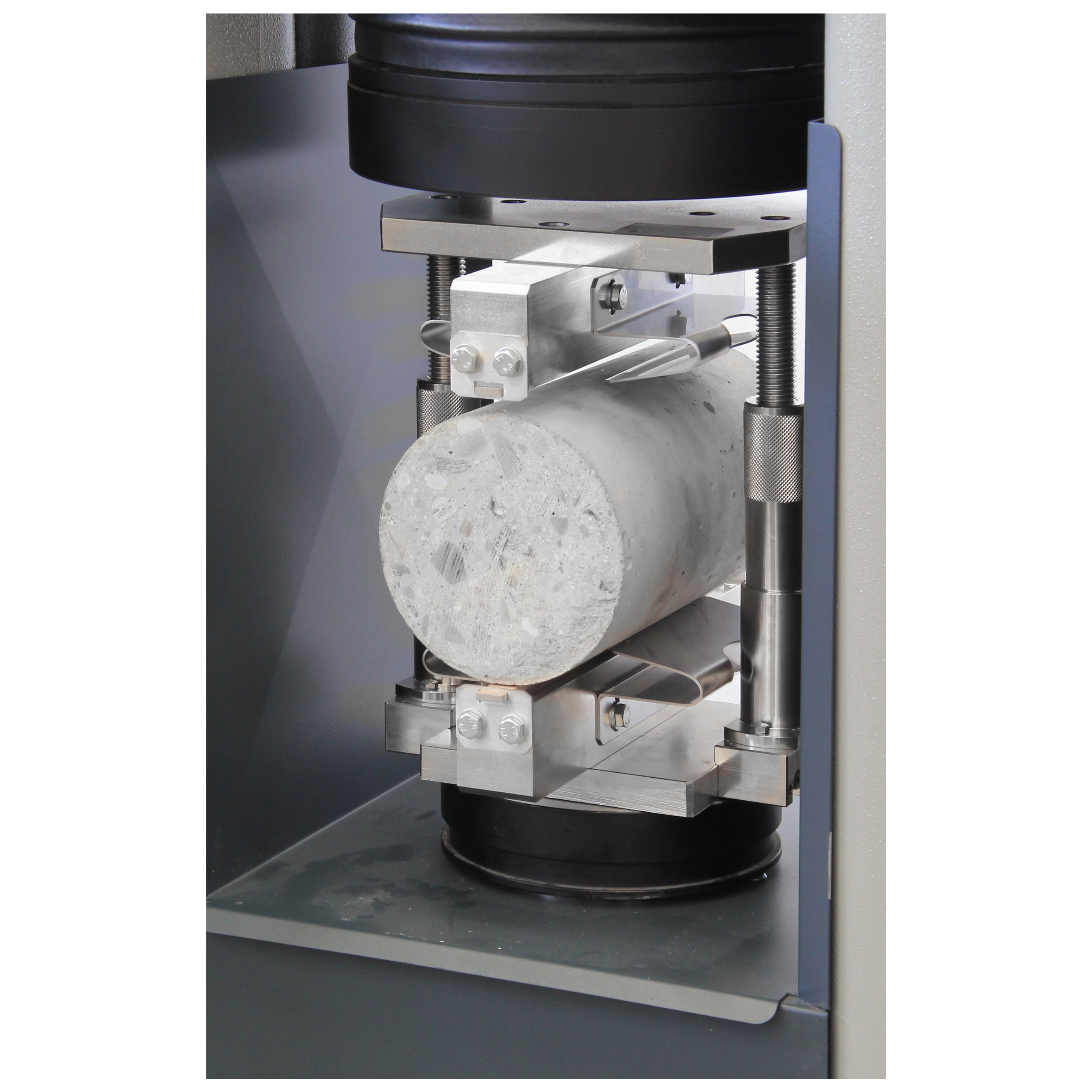

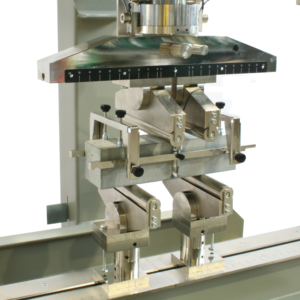

Electronic Universal Extensometer / Compressometer

Axial Compression Device

Extras and Upgrades

Third and Fourth Frame Facility

General Inquiries

There are no inquiries yet.