- DESCRIPTION

- Description

- Store Policies

- Inquiries

HIGHLIGHTS

How it works

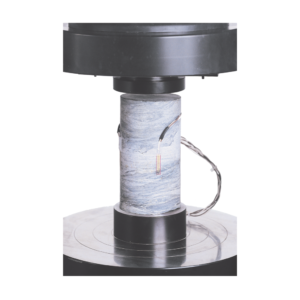

An ultrasonic wave is sent from a transmitter to a receiver and is conveyed automatically by the device along the entire length of the pile via the pipes embedded into it during casting. The speed of the sonic wave and its energy are strongly influenced by the quality of the concrete and it is therefore possible to assess the characteristics and give a tomographic representation in 2D called diagraphy.

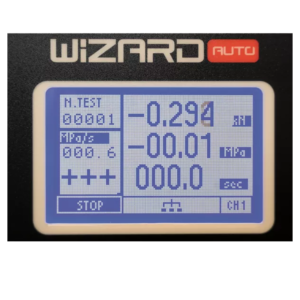

Cross-Hole Analyzer, a complete system

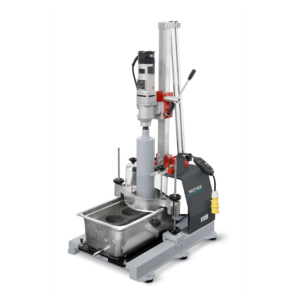

The instrument is a complete system for performing structural tests by ultrasound on piles, deep foundations, infrastructural works or buildings.

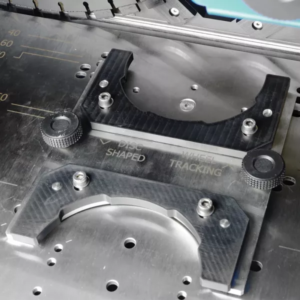

Each reel system has a 52 kHz motorized probe with 60 m of cable and also houses the battery plus all the electronic controls that automatically manage the probes during the descent/ascent phases (cross-hole) and saving of the test data.

The configuration practically eliminates the need for physical cables and is supplied with a Rugged tablet which allows the setting of all parameters, test management, and display/processing of the acquired test data in an easy, immediate and wireless way.

The system can directly manage up to 4 motorized coil systems from one tablet. Using 2, 3 or 4 motorized reels it is possible to increase the survey productivity and reduce testing time: with a single ascent/descent of the probes in the pile to be checked (which must have 2, 3 or 4 integral pipes) it is possible to obtain results for the corresponding sections.

The data are acquired at each pulse and displayed in real time on the tablet screen allowing any imperfections in the structure being inspected to be seen immediately.

Fully automatic

The procedure for running cross-hole surveys with 2, 3 or 4 channels is managed in a fully automated way. The only manual operations required are the positioning of the encoders for reading the position of the motorized probes on the pipes and the initial alignment of the probes on the pile head.

The test is started by simply pressing a button and it is possible to verify the test data step-by-step in order to check the test progress in real time.

FEATURES

- Integrated wireless system with:

- 2 motorized reels

- expansion options for 1 – 2 channels

- multi-reels system (up to 4): the investigation is performed providing complete information on pile quality and homogeneity over its whole length

- system completely managed via a rugged Android tablet (included)

- easily transportable with the very small wheeled suitcase

- user-friendly and intuitive software.

SPECIFICATION

Acquisition:

- time bases: 100 ns; 200 ns; 500 ns; 1 us; 2 us; 5 us; 10 us; 20 us

- sample resolution: 12 bit

- samples per event: 2048

- amplification factors: x1; x2; x4; x5; x8; x10; x16; x32

- band width: 50 MHz

- filter for ultrasounds: central frequency 50 kHz

Probes

- hole: resonant frequency of 52 kHz, diameter 35 mm

- peak excitation voltage: 500 V (standard) 2000 V (high)

- maximum pulse output frequency: 1 per second

- measuring step increment: 10 mm

- motorized reels: 2, 3 or 4 no. with 60 m cable

- position encoder: 2, 3 or 4 no.; accuracy 1.4 °

- speed and alignment: managed automatically

- hardware buttons for drive motors

- automatic switching transmit / receive ultrasonic

General

- complete control from Panasonic Rugged tablet with dedicated Android application

- conforming to ASTM D6760-08

- wireless technology: WiFi – 2.4 GHz – 802.11 b

- wireless synchronization: 5 GHz, 8 selectable channels

- selection radio channel: automatic

- power supply: 12V DC, 1 Li-Ion battery 10,5Ah for each reel

- average intake (per reel): 180mA (standby) – 600mA (during measurement)

- diagraphy processing software: compatible with Microsoft Windows® operating systems

- ambient operating conditions: -20 to 80 ° C

- single unit dimensions: 220x250x225 mm (L x W x H)

- carrying case dimensions: 538x406x269 (L x W x H)

- single unit weight approx.: 9.3 kg

- carrying case with two complete units weight: 28 kg

ACCESSORIES

MODELS

General Inquiries

There are no inquiries yet.