HIGHLIGHTS

PILOT PRO is the best choice for Qualtiy Control laboratories to carry out a high throughput of routine failure tests including compression, flexure and indirect tensile tests.

PILOT PRO introduces new features and capabilities that will revolutionize the operations of any progressive construction quality testing laboratories.

LinkLAB is CONTROLS’ new proprietary Laboratory Connectivity Package.

It allows your PILOT PRO to be a connected part of your laboratory infrastructure by taking inputs from any number of ancillary measuring systems and devices increasing efficiency and eliminating transposing errors.

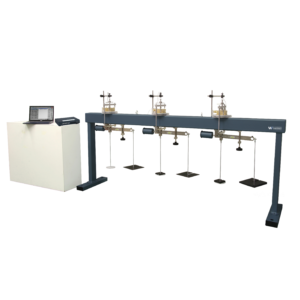

Frames

These machines, featuring a very rigid four columns frame, have been designed for the testing of the cement prism either in compression or in flexure.

Three versions are available:

65-L27P1x

models, double testing chamber, 15/300 kN cap., inbuilt flexural jig for 40x40x160 cement prisms and compression apparatus for portions of 40x40x160 mm prisms broken in flexure.

Conforming to EN 196-1, 1015-11.

65-L28P1x

models, double testing chamber, 15/300 kN cap., fitted with round platens for testing in compression and flexion cement, mortar, resins and other materials.

Conforming to EN 196-1, 1015-11, ASTM C109, C348, C349 using the suitable accessories.

65- L18P1x

models, 300 kN cap., fitted with round platens for testing cement, mortar, resins and other materials and other materials. Conforming to EN 196-1, 1015-11, ASTM C109, C349 using the suitable accessories.

All models are fitted with high accuracy load cell/s.

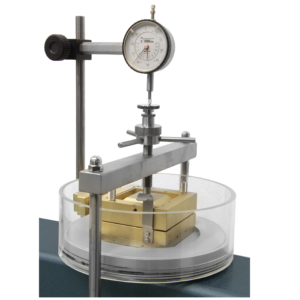

Models fitted with compression platens 165 mm dia. (L28Pxx,L18Pxx) have a vertical span of 200 mm hence can house all standard accessories for cement and mortar testing (see accessories) and furthermore can be used to test other specimens directly on the standard compression platens adjusting, if necessary, the vertical daylight, with the suitable distance pieces (see accessories). Compression platens can be supplied complete with Platen surface hardness certificate.

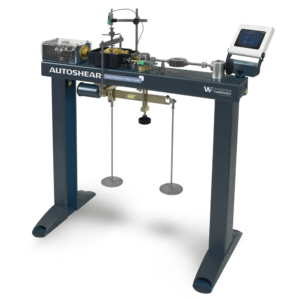

PILOT PRO, Automatic power and control system

See technical specifications.

Safety features

Includes: Max. pressure valve to avoid machine overloading; piston travel limit switch; emergency stop button; front door and rear transparent fragment guard on request.

FEATURES

Smart automatic and connected Power and Control System for standard failure testing.

PILOT PRO is the best choice for Qualtiy Control laboratories to carry out a high throughput of routine failure tests including compression, flexure and indirect tensile tests.

- Huge boost in efficiency and error elimination: LinK-LAB – Integrated testing station solution for seamless connection and data inputs from many ancillary devices for dimensional measurement, weight, bar code, etc.

- Automatic – time saving: test-cycle automation maximizes productivity and ensures tests are performed accurately according to pre-set methods, eliminating operator variables.

- Highly accurate and energy saving: Our DC motor technology quietly and efficiently delivers super accurate load control at both low-speed and low-loads.

- Intuitive, quick and simple operation: The integrated control system features an intuitive 7” color graphical display, which works like a tablet or smart-phone, and makes PILOT PRO quick and simple to operate.

- Standards compliant – peace of mind: Hardware and firmware are in total compliance with all the main international testing standards

- Multilingual functionality: The system is available in multiple languages and is fully compatible with non-Latin characters for Chinese, Cyrillic (and more).

SPECIFICATION

Hydraulics

- Dual-stage pump: centrifugal low pressure for fast approach automatically switches to radial multi-piston high pressure for loading

- DC motor, 720W, 50-60Hz

- Maximum working pressure 700 bar

- Load/unload valve

- Second/third frame selection valve available as option

Hardware

- 524,000 points high-resolution/stability analog channels

- 3 channels for load sensors

- Control frequency 250 Hz

- Sampling frequency 250 Hz

- 5.1”, 800 x 480 pixel, 16 M colors, icon-driven capacitive sensing touchscreen graphic display

- Unlimited storage capacity for test data on internal 16 GB SD card

- USB port for test data storage on external USB memory stick and for firmware upgrade

- Ethernet port for PC / Internet /network communication

- Optional integrated graphic printer including Load-Time plot

- RS 232 port for data downloading in ASCII format

Firmware

- Execution of compression, flexure, indirect tensile, ACV tests in automatic mode with load rate controlled by a closed-loop P.I.D. system

- Execution of loading ramps with the possibility to manually increase or decrease the test speed during the test

- Pause command to maintain steady load can be enabled at a pre-set value before the test or as required while testing

- Simultaneous display of load, specific load, actual load rate, load/time graph

- Saving of the specimen failure type (to EN or ASTM) in the test results

- Download data to internal printer (optional) or to PC via RS 232 port or to USB memory stick

- PC / network communication via Ethernet

- Multi-coefficient linearization of the calibration curve for better accuracy at low loads thus avoiding the use of a second pressure transducer

- Recording facility for up to 9 test profiles for each channel including: type of test (e.g. compression, flexural, indirect tensile), specimen size and shape, load rate, test standard and other general information. Each one of the recorded test profiles can be recalled automatically to save time

- Improved PID algorithm and multi PID selection. Up to 3 different PID settings can be tuned for a variety of materials (e.g. cylinder with neoprene pads, low strength specimens) and test methods (e.g ACV, flexure, indirect tensile).

- Compatible with the newly released Datamanager software, tailored for construction material testing laboratories, for real-time data acquisition, display and management

- Peripheral devices integration with Link-LAB

- Automatic load measurement verification procedure, by connecting suitable load cells and our digital readout unit to PC

- Language selection (including Cyrillic and Chinese)

- Unit selection (kN, ton, lbf)

- USB port for firmware upgrade and safe backup of the original configuration data (PID, calibration, etc.), in case of loss and/or data corruption. The restore of the machine to the factory settings is easy avoiding the need of any technical support.

MODEL

65-L18P12

PILOT PRO automatic compression machine, 300 kN cap. for compression tests on cement, mortar, resin and other materials. Conforming to EN 196-1, 1015-11, ASTM C109, C349 using the suitable accessories. – High-stiffness 4-columns frame – High accuracy load cell for load measurement – Compression platens 165mm diameter – PILOT PRO automatic control system – PID Closed loop control of the load rate – High control and data sampling frequency: 250 Hz- Variable speed permanent magnet DC motor for superior performances at low load rates and low load values – 5.1″, 800 x 480 pixels, 16 M colors, icon-driven capacitive sensing touchscreen graphic display – RS232 serial port for data transmission (including load/time values for graph plot) in ASCII format – USB port for data storage, export to PC and firmware upgrade – Ethernet port for PC / Internet /network Communication – Integrated printer available on request – 8 GB Internal permanent memory on SD card – 524000 points high-resolution/stability channels- Dayligths: horizontal 220mm, vertical 200mm – Piston travel 50 mm – Limit switch preventing piston overtravel – Load measurement accuracy: class 1 to EN 12390-4 /class A to ASTM E74 starting from 30kN. Special calibration from 3 kN available on request – Supplied complete with traceable calibration certificate for load measurement accuracy – Optional transparent rigid safety guard 230V/50-60Hz/1Ph

65-L18P14

PILOT PRO automatic compression machine, 300 kN cap. for compression tests on cement, mortar, resin and other materials. Conforming to EN 196-1, 1015-11, ASTM C109, C349 using the suitable accessories. – High-stiffness 4-columns frame – High accuracy load cell for load measurement – Compression platens 165mm diameter – PILOT PRO automatic control system – PID Closed loop control of the load rate – High control and data sampling frequency: 250 Hz- Variable speed permanent magnet DC motor for superior performances at low load rates and low load values – 5.1″, 800 x 480 pixels, 16 M colors, icon-driven capacitive sensing touchscreen graphic display – RS232 serial port for data transmission (including load/time values for graph plot) in ASCII format – USB port for data storage, export to PC and firmware upgrade – Ethernet port for PC / Internet /network Communication – Integrated printer available on request – 8 GB Internal permanent memory on SD card – 524000 points high-resolution/stability channels- Dayligths: horizontal 220mm, vertical 200mm – Piston travel 50 mm – Limit switch preventing piston overtravel – Load measurement accuracy: class 1 to EN 12390-4 /class A to ASTM E74 starting from 30kN. Special calibration from 3 kN available on request – Supplied complete with traceable calibration certificate for load measurement accuracy – Optional transparent rigid safety guard 110V/60Hz/1Ph

65-L27P12

PILOT PRO automatic double chamber compression machine, 15/300 kN cap. for compression and flexure tests on cement/mortar prisms 40x40x160mm.Conforming to EN 196-1, 1015-11. – High-stiffness 4-welded-columns frame – High accuracy load cells for load measurement – Incorporating load devices: 40x40mm platens and flexural jig – PILOT PRO automatic control system – PID Closed loop control of the load rate – High control and data sampling frequency: 250 Hz- Variable speed permanent magnet DC motor for superior performances at low load rates and low load values – 5.1″, 800 x 480 pixels, 16 M colors, icon-driven capacitive sensing touchscreen graphic display – RS232 serial port for data transmission (including load/time values for graph plot) in ASCII format – USB port for data storage, export to PC and firmware upgrade – Ethernet port for PC / Internet /network Communication – Integrated printer available on request – 8 GB Internal permanent memory on SD card – 524000 points high-resolution/stability channels- Dayligths: horizontal 220mm, vertical 50/50mm – Piston travel 30/50mm – Limit switch preventing piston overtravel – Load measurement accuracy: class 1 to EN 12390-4 /class A to ASTM E74 starting from 30kN for 300 kN chamber and from 1.5kN for 15kN chamber. Special calibration from 3kN for 300kN chamber and from 0.5kN for 15kN chamber available on request. – Supplied complete with traceable calibration certificate for load measurement accuracy – Optional transparent rigid safety guard 230V/50-60Hz/1Ph

65-L27P14

PILOT PRO automatic double chamber compression machine, 15/300 kN cap. for compression and flexure tests on cement/mortar prisms 40x40x160mm.Conforming to EN 196-1, 1015-11. – High-stiffness 4-welded-columns frame – High accuracy load cells for load measurement – Incorporating load devices: 40x40mm platens and flexural jig – PILOT PRO automatic control system – PID Closed loop control of the load rate – High control and data sampling frequency: 250 Hz- Variable speed permanent magnet DC motor for superior performances at low load rates and low load values – 5.1″, 800 x 480 pixels, 16 M colors, icon-driven capacitive sensing touchscreen graphic display – RS232 serial port for data transmission (including load/time values for graph plot) in ASCII format – USB port for data storage, export to PC and firmware upgrade – Ethernet port for PC / Internet /network Communication – Integrated printer available on request – 8 GB Internal permanent memory on SD card – 524000 points high-resolution/stability channels- Dayligths: horizontal 220mm, vertical 50/50mm – Piston travel 30/50mm – Limit switch preventing piston overtravel – Load measurement accuracy: class 1 to EN 12390-4 /class A to ASTM E74 starting from 30kN for 300 kN chamber and from 1.5kN for 15kN chamber. Special calibration from 3kN for 300kN chamber and from 0.5kN for 15kN chamber available on request. – Supplied complete with traceable calibration certificate for load measurement accuracy – Optional transparent rigid safety guard 110V/60Hz/1Ph

65-L28P12

PILOT PRO automatic double chamber compression machine, 15/300 kN cap. for compression and flexure tests on cement, mortar, resin and other materials. 230 V, 50-60 Hz, 1 Ph

65-L28P14

PILOT PRO automatic double chamber compression machine, 15/300 kN cap. for compression and flexure tests on cement, mortar, resin and other materials. 110 V, 60 Hz, 1 Ph

ACCESSORIES

50-C0050/HRD5

Supply of L27xxx compression machine complete with traceable certificate of hardness of testing platens surfaces (upper and bottom platen certification included). Available only for ordering with compression machine.

65-L0050/HRD

Supply of the machine cement machines/frames L28xxx complete with traceable certificate of hardness of testing platens surfaces (one upper and one bottom platen certification included). Available only for ordering with machine.

50-SW/DM

DATAMANAGER PC software compatible with DIGIMAX, PILOT, AUTOMAX, PILOT PRO, AUTOMAX PRO and PRO-M. Suitable for remote control of the system (except DIGIMAX), data acquisition, processing and filing. LAN cable included.

50-Q60P/PRINT

Upgrading the AUTOMAX PRO and PILOT PRO series to incorporate a serial graphic printer in the rear panel allowing load/time plot (printing available for languages with latin charcters only)

50-Q60P/PR

Upgrading the AUTOMAX PRO and PILOT PRO series to incorporate a serial graphic printer in the rear panel allowing load/time plot.

65-L1000/20

Distance piece 165 mm dia. x 20 mm height.

65-L1000/30

Distance piece 165 mm dia. x 30 mm height.

65-L1000/40

Distance piece 165 mm dia. x 40 mm height.

65-L1000/68

Distance piece 165 mm dia. x 68 mm height.

50-KLAB/E

LinK-LAB Enterprise laboratory connectivity package for machines controlled by PC via DATAMANAGER Software.

65-L0050/P

Safety guard opening switch for L type frames and machines

65-L2701/P

Transparent rigid safety guard for testing frame series 65-L27xxx. Suitable only for models fitted with load cells

65-L2800/P

Transparent rigid safety guard for testing frame series 65-L28xxx.

Calibration 65-L18P1x as class 1 with:

50-C0050/CAL

Special calibration of load digital readout unit assuring class 1 from 1% of testing machine full scale (maximum load)

50-C0050/1CAL

Special calibration of load digital readout unit assuring class 1 from 0.1% of testing machine fullscale (Class 1 accuracy from 0.5 to 500 kN). Available only for C92P1x machines.

Calibration 65-L27P1x, 65-L28P1x as class 1 with:

50-C0050/CAL5

Special calibration of load digital readout unit assuring class 1 from 5% of testing machine full scale (maximum load)

50-C0050/CAL

Special calibration of load digital readout unit assuring class 1 from 1% of testing machine full scale (maximum load)

General Inquiries

There are no inquiries yet.