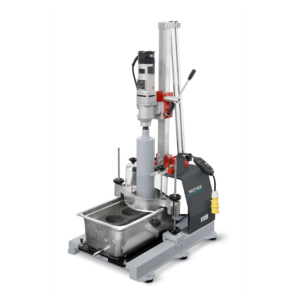

AMPT PRO Asphalt Mixture Performance Tester

$30,000.00

AMPT PRO, designed with the latest technologies and product developments, once again sets the benchmark for innovation and performance. It fully complies with AASTHO T378/TP79 and can easily perform the three asphalt tests of NCHRP projects.

- DESCRIPTION

- Description

- Store Policies

- Inquiries

DESCRIPTION

HIGHLIGHTS

The Asphalt Mixture Performance Tester can be used as part of your Superpave performance based testing program.

This original Asphalt Mixture Performance Tester (AMPT) is the culmination of two National Cooperative Highway Research Program (NCHRP) projects. IPC Global has been involved in IPC Global equipment, and has been successfully evaluated by NCHRP.

Standard outfit

AMPT Pro includes, as standard, the following testing Modules (compression platens) which, however, have been completed with the transducer kit accessory.

Dynamic Modulus E to AASHTO T378/TP79 and NCHRP 9-29

A performance.related property, for asphalt mixture evaluation and charachterising the stiffness of HMA. It is an important input parameter for AASHTO “Mechanistic-Empirical Pavement Design Guide”.

- Creates master curves for structural design

- Assess modified binders and local materials

- Forensisc analysis of pavement failure

Flow number to AASHTO T378 and NCHRC 9-29

Flow number is related to the resistance of HMA to permanent deformation.

- Repeated load creep tests

- Evatluate rutting

- Accurate simulation of actual loading

Flow time to NCHRP 9-29

Flow time is a quick and simple measurement of the resistance of HMA to permanent deformation.

- Static creep tests

- Measure permanent deformation for rutting evaluation

- Load Capacity: Static: 19kN, Dynamic 17kN

- Frequency Range: Up to 100Hz

- Actuator Stroke: 30mm (+/- 15mm stroke)

- Actuator Type: Labyrinth Bearing

- Specimen Size (dia xh): 100 x 150 mm nominally, 50 x 135 mm, 38 or 50 x 110 mm

- Temperature Range: -10 ° C to + 70 ° C *

- Cooling Rate: Typically cools to + 4 ° C in under 30 minutes (at an ambient temperature of + 23 ° C)

- Temperature Accuracy: +/- 0.2 ° C (at temperature probe placed close to the specimen)

- Cell Dimensions (dia xh): 305 x 420mm

- Confining Pressure: 0 to 225 kPa

- Noise Level: Less than 70dB at 2m

- Computer Control: Integrated all-in-one PC touchscreen (optional)

- Air Compressor and Dryer: Low noise, integrated, automated operate-on-demand (optional)

- Easily interchangeable load cells test

- Supplied complete with high quality pre-filtered oil for longer life

- Dimensions (hxwxd): 1,359 x 1,350 x 739mm

- Weight: 275kg (including oil)

Transducers

- Load Cell: Low profile pancake type

- Built-in LVDT Actuator: 30mm Stroke

- Pressure: 0 to 225 kPa

- On-Specimen Displacement: 3 clips on +/- 0.5mm LVDTs Compatible with up to 4 (Various optional loose-core, strain gauge transducers available)

- Temperature Probe Range: from -25 up to +80° C

- Plug-and-Play: Up to 4 interchangeable on-specimen displacement transducers, plus easily interchangeable load cells

Services

- Power (without air compressor): 220V–240V, 50Hz, single phase, 17A 208V, 60Hz, single phase, 20A

- Power (with air compressor): 220V–240V, 50Hz, single phase, 22A 208V, 60Hz, single phase, 25A

- Air: Clean dry air at 450-800kPa; 2 L/sec (Optional integrated air compressor available)

- Hydraulic Oil: Pre-filled with high specification pre-filtered, ISO 46 Premium Mineral Oil

Control & Data Acquisition—IMACS2

- Configuration: Fully integrated

- Real Time Digital Computer Control: 32-bit Processing

- Acquisition Speeds: 200kHz (simultaneous on all channels)

- Data Over-Sampling: At least 4x

- Data Resolution: 24-bit auto-ranging data acquisition

- Communication: Ethernet at 10/100Mb/s, Ethernet at 1Gb/s

- Analogue Inputs: Auto-calibrate on power up

- Analogue Outputs: 8 BNC connectors for raw data logging

- Control: 2 axis control (actuator and confining pressure)

- Acquisition: Up to 8 Channel data acquisition (actuator displacement, axial load, 3 to 4 on-specimen displacement transducers, confining pressure and temperature)

ACCESSORIES

Small diameter accessories

Proving Ring

Compressor Assembly

LVDT Assembly

Consumable Kit

Touch Screen

- Significantly improved ECU performance and innovation

- The new Hydraulic Power Supply (HPS) uses inverter technology coupled with a high performance labyrinth bearing actuator to deliver 19 kN of force

- Easy-to-use and ergonomic testing system

- Interchangeable transducers and load cells with “plug and play” signal conditioners allowing for quick and easy transition of test set-ups

- Clarity in results with the 3rd Generation Integrated Multi Axis Control System (IMACS2)

- All-in-One computer control with the latest All-in-One touchscreen PC technology

- Fully integrated and compact in design, a perfect solution for both static and mobile testing facilities

- Data output is fully compatible with FHWA FlexMAT™ and FlexPAVE™ software

- Optional air compressor that comes integrated

Description

Store Policies

Inquiries

General Inquiries

There are no inquiries yet.