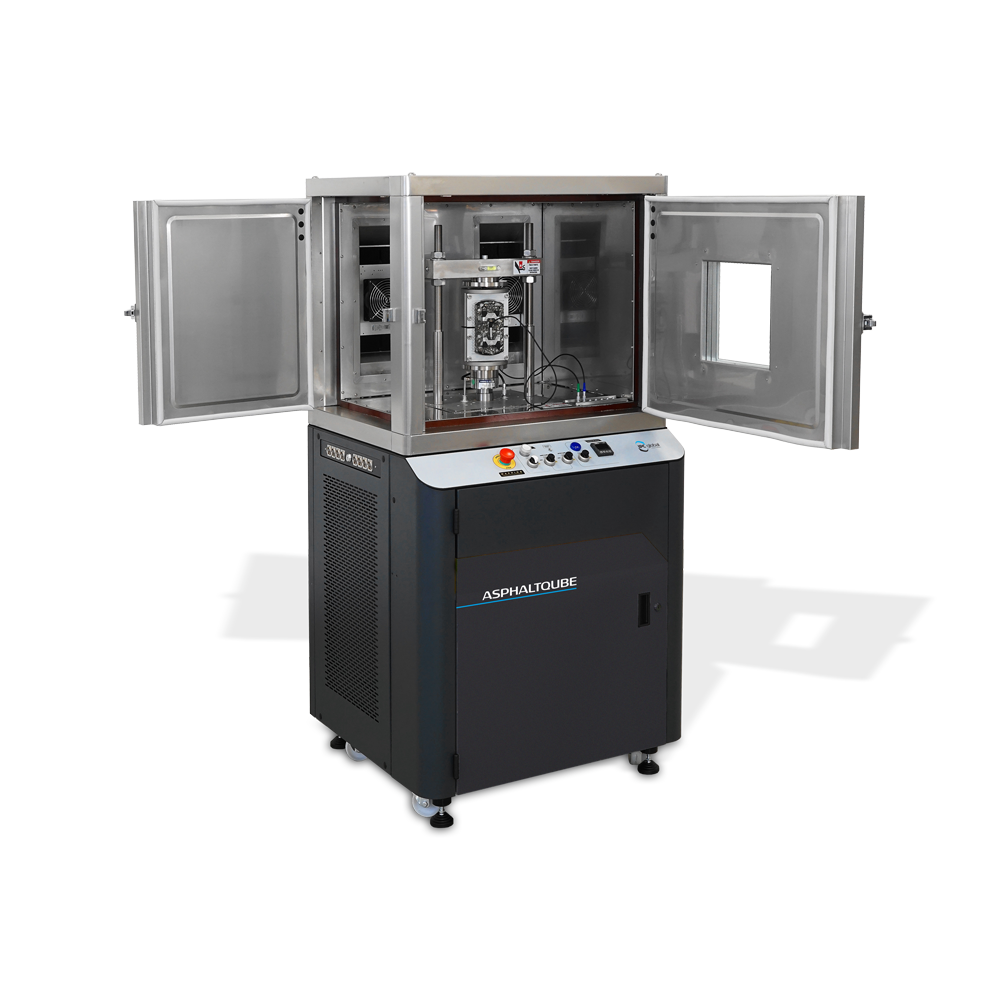

AsphaltQube – Modular Electro-Mechanically Operated Asphalt Tester

$22,000.00

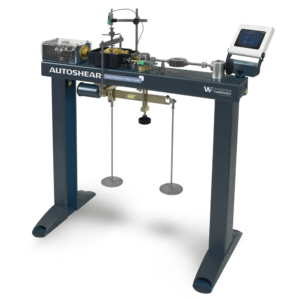

Now you can perform the most common asphalt standards tests in one compact, modular, easy to use all-in-one tester, the AsphaltQube. This standard testing system uses the efficient EmS Electro-mechanical Servoactuated technology and is perfect for QC and QA tests.

- DESCRIPTION

- Description

- Store Policies

- Inquiries

DESCRIPTION

HIGHLIGHTS

The AsphaltQube can be used as part of your SuperPave performance based testing program.

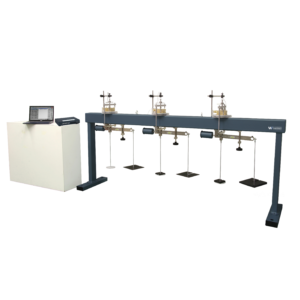

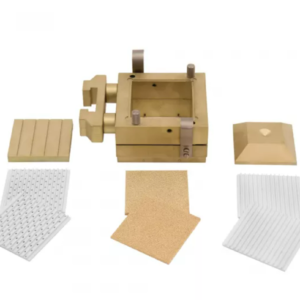

The flexible system allows you to perform the test with AMPTQube (permanent deformation, cyclic compression, indirect tensile stiffness, indirect tensile fatigue, crack propagation, direct tension-compression, dynamic / complex modulus) plus triaxial compression, four-point and two -point stiffness and fatigue flexural tests.

Main benefits:

- Brand new technology including the new revolutionary EmS actuator

- Easy and versatile with a fully integrated modular system, that includes a 15 kN capacity CEMA1 actuator

- Enhanced environmental cabinet (to be added as option) that grants a wide temperature range with fast and accurate temperature control

- Easy-to-use and ergonomic testing system

- Clarity in results with the 3rd Generation Integrated Multi Axis Control System (IMACS2)

- Fully integrated and very compact in design, a perfect solution for both static and mobile testing facilities

- Optional air compressor that comes integrated in the machine

- All-in-one touchscreen PC (optional)

- Load capacity: Static 10 kN, Dynamic 15 kN

- Frequency range: Up to 100Hz

- Actuator stroke: 30 mm (+/- 15 mm stroke)

- Actuator type: E-Mech electro-mechanical actuator CEMA1

- Noise level less than 70 db at 2m

- Computer control: integrated all-in-one PC touch screen (optional)

- Temperature controlled cabinet: required, to be ordered separately depending on the required range (see accessories)

- Air compressor and dryer: low noise, integrated, automated-on-demand (optional)

- Dimensions (H x W x D): 1630 x 830 x 830 mm with environmental chamber (to be ordered separately)

- Weight :: 250kg

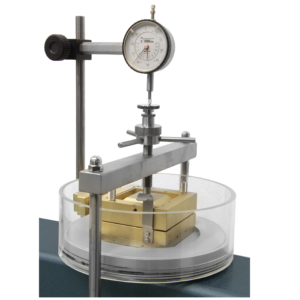

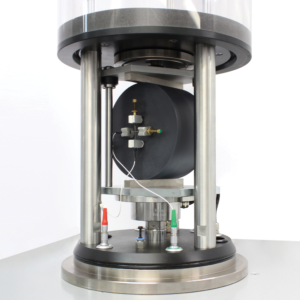

Transducers

- Load cell: low profile pancake type

- Built-in LVDT actuator: 30 mm stroke

- Plug-and-Play: up to 8 channels

Services

- Power without air compressor: 230 V, 50 Hz, single phase, 9 A; 110 V, 60 Hz, single phase, 18 A

- Power with air compressor: 230 V, 50 Hz, single phase, 11 A; 110 V, 60 Hz, single phase, 22 A

- Air: Clean dry air at 450-800 kPa; 2 L / sec (optional integrated air compressor available)

ACCESSORIES

Accessories and Spare Parts

EmS technology’s main benefits:

- Improved dynamic performance over servo-pneumatics

- Stand-alone with no need of compressed air supply

- Lower maintenance

- Robust and durable giving a more resilient solution

- Compact design requiring, in general, a smaller footprint

- Easy to use

Description

Store Policies

Inquiries

General Inquiries

There are no inquiries yet.