- DESCRIPTION

- Description

- Store Policies

- Inquiries

DESCRIPTION

HIGHLIGHTS

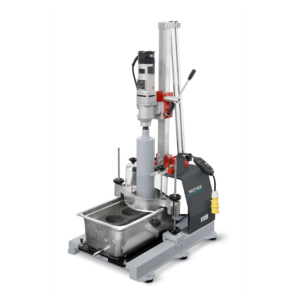

The Rock Shear Box Apparatus was originally developed at Imperial college, London, by Professor E. Hoek. It is a simple and practical method of determining the strength and slope stability of rock, both in the field and in the laboratory.

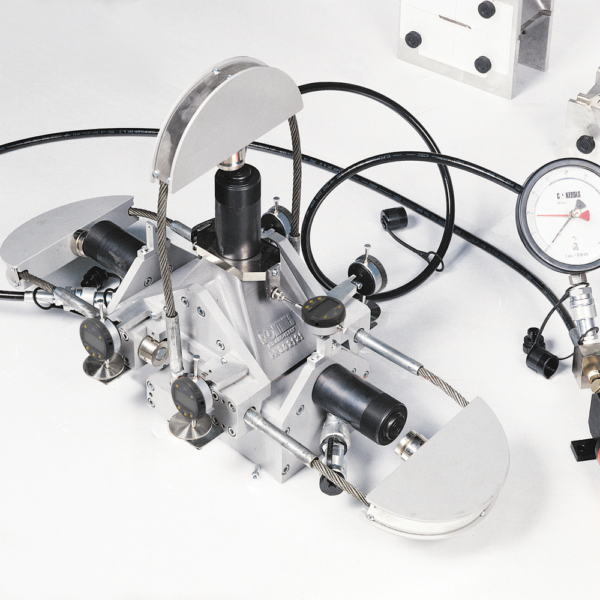

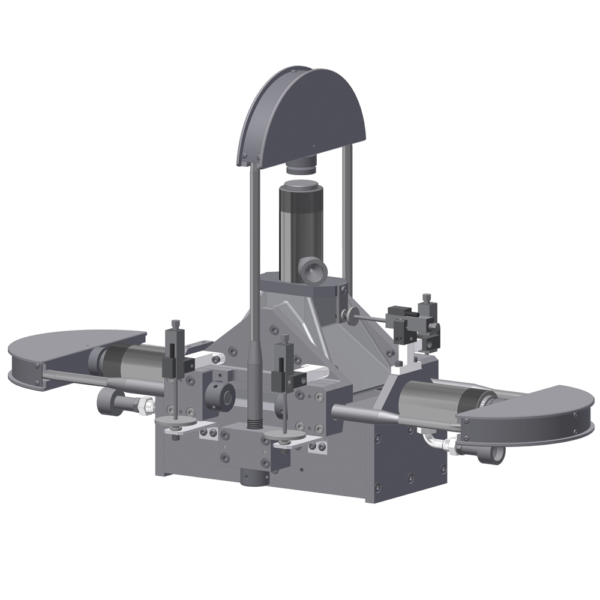

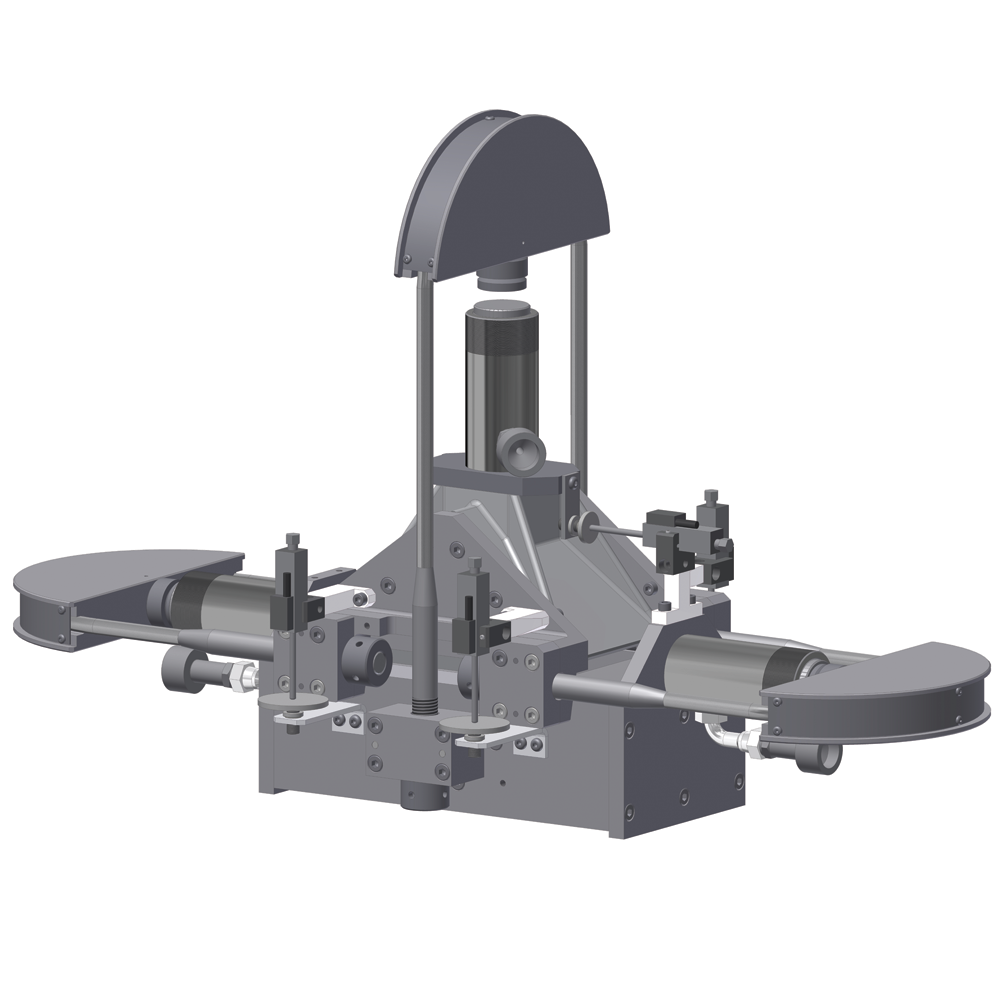

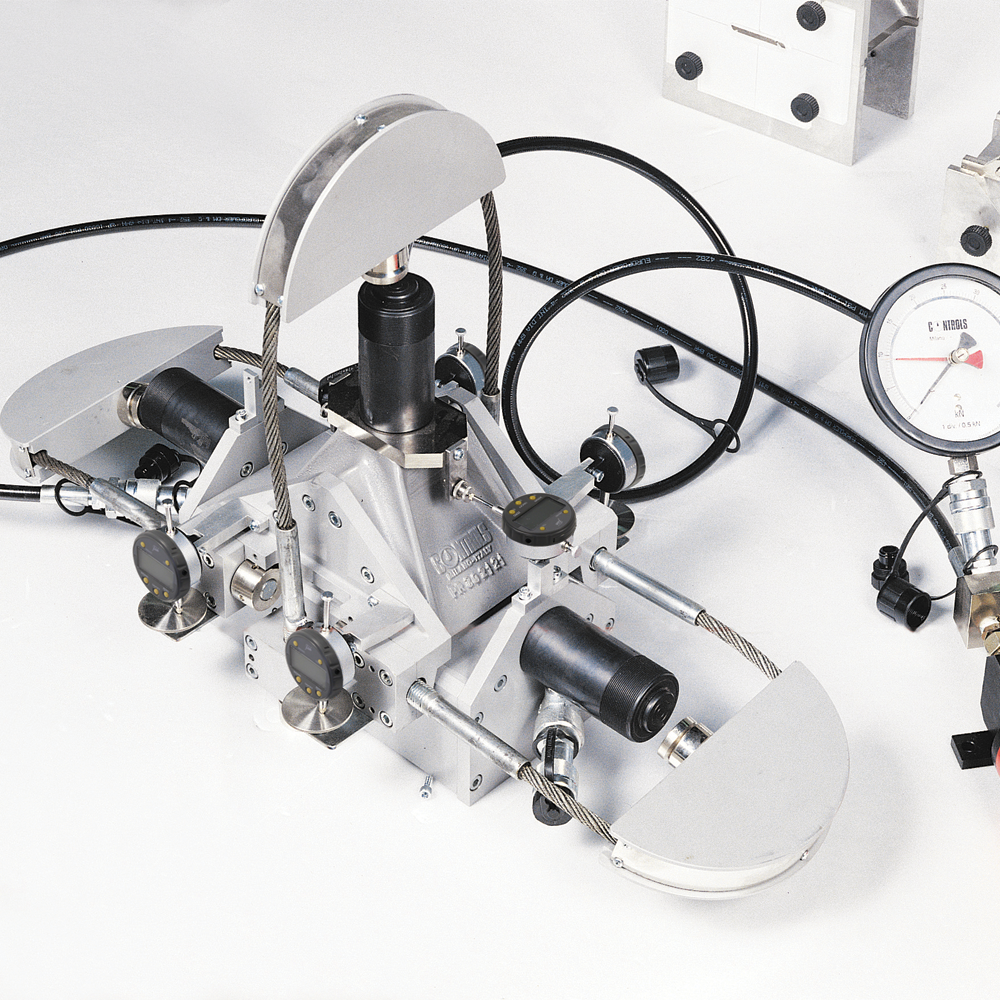

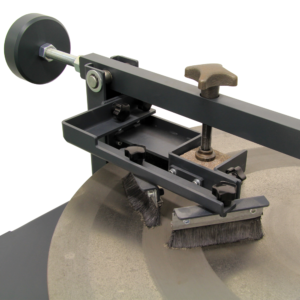

The apparatus consists of a shear box designed to accept samples not larger than 115×125 mm, or alternatively cores up to 102 mm dia. The shear box consists of two halves, the upper being connected to two rams for reversible shearing action and the lower connected to a ram for normal load application. The loads are recorded by Bourdon tube load gauges or by pressure transducers (in this case external datalogger is needed).

The normal loading system is complete with an adjustable low friction pressure maintainer to absorb volume changes of the specimen during the shearing action and to ensure a constant vertical stress.

FEATURES

This apparatus was originally developed at Imperial college, London, by Professor E. Hoek. It is a simple and practical method of determining the strength and slope stability of rock, both in the field and in the laboratory. The apparatus consists of a shear box designed to accept samples not larger than 115×125 mm, or alternatively cores up to 102 mm dia. The shear box consists of two halves, the upper being connected to two rams for reversible shearing action and the lower connected to a ram for normal load application. The loads are recorded by Bourdon tube load gauges or by pressure transducers (in this case external datalogger is needed).

The normal loading system is complete with an adjustable low friction pressure maintainer to absorb volume changes of the specimen during the shearing action and to ensure a constant vertical stress.Two versions are available:

- Basic model. It is supplied complete with: 5 digital gauges 25×0.001 mm (4 vertical and 1 horizontal); 2 mould formers; 2 hand operated pumps for lateral and vertical load fitted with Bourdon gauges. The pump for vertical load is fitted with a pressure maintainer to assure uniform load during the test.

- Electronic model. It is supplied complete with; 5 potentiometric transducers with 25mm travel (4 vertical and 1 horizontal); 2 mould formers; 2 hand operated pumps for lateral and vertical load fitted with Bourdon gauges; 2 pressure transducers for the direct acquisition of the load values. The pump for vertical load is fitted with a pressure maintainer to assure uniform load during the test.

Displacement and load readings shall be acquired by suitable datalogger that has to be add as accessory. Two versions can be used to complete the testing configuration: standard model with dedicated display suitable for laboratory use or with battery operated model for on-site use. For more info please refer to Releted Products below and Accessories section.

SPECIFICATION

- Max. axial and shear load capacity (for both models): 50 kN

- Manometers range (for both models): 50 kN x 1 kN

- Displacement reading (for Basic model): 5 digital gauges 25×0.001 mm

- Displacement reading (for Electronic model): 5 potentiometric transducers with 25mm travel

- Max. sample dimensions: up to dia. 102 mm (for core specimens) and 115 mm x 125 mm (for prism specimens)

- Overall dimensions (loading frame only): 460x250x600 mm

- Weight approx.: 45 kg

Datalogger

Cables

Spare parts

Template for data processing

Description

Store Policies

Inquiries

General Inquiries

There are no inquiries yet.